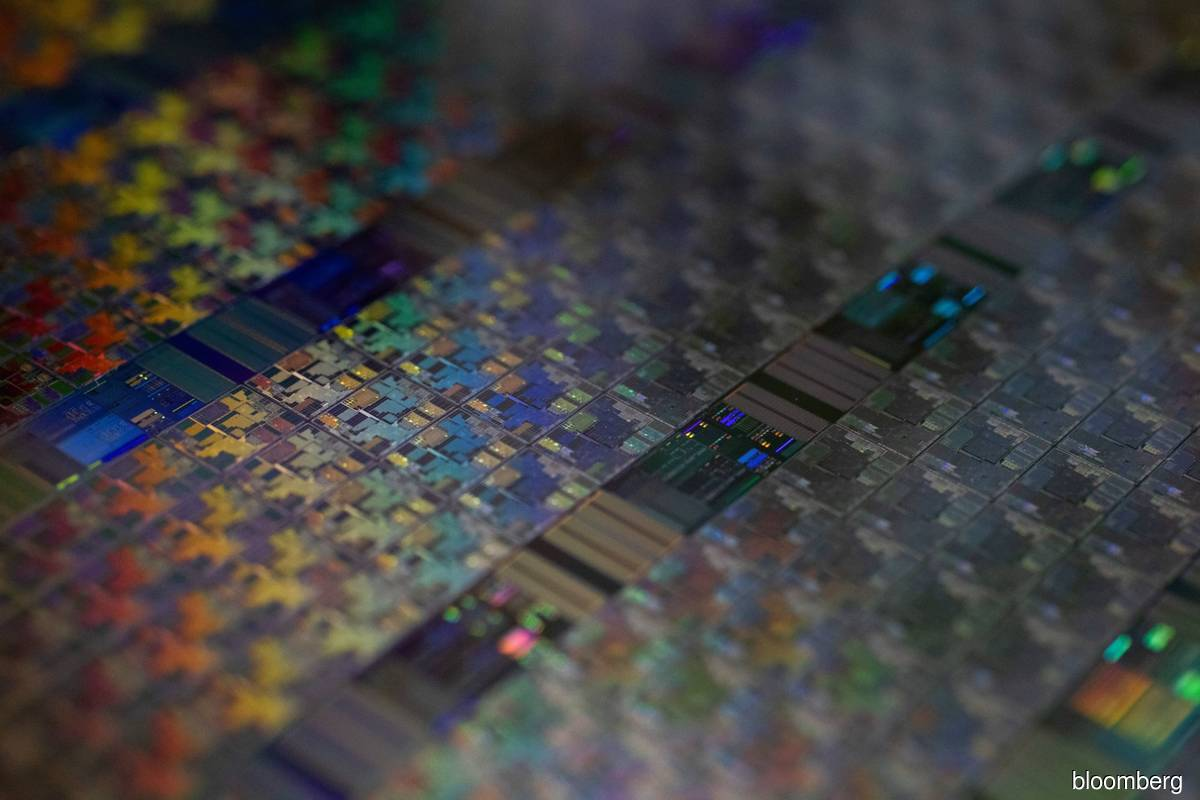

Moody’s: Chip shortage to normalise in 2023

The chip shortage is expected to normalise sometime in 2023, after witnessing some lead times remaining elevated through the end of the year, says Moody’s Analytics economist Tim Uy.

Moody’s分析经济学家Tim Uy表示,在目睹到年底的一些交货时间仍然延长之后,预计芯片短缺将在 2023 年的某个时候恢复正常。

He said for the first time since the start of the pandemic, the aggregate semiconductor chip lead time fell last month, though ever so slightly.

他表示,自大流行开始以来,上个月半导体芯片的总交货时间首次下降,尽管幅度很小。

“One of the best metrics for assessing supply-chain stress has been semiconductor chip lead times — the time it takes for a microchip that is produced to reach the end consumer — as semiconductor chips are the oil of the digital economy.

“评估供应链压力的最佳指标之一是半导体芯片的交货时间——生产的微芯片到达最终消费者所需的时间——因为半导体芯片是数字经济的石油。

“They power practically all electronic devices including cars, computers, sensors, gaming consoles, ovens and so on,” he said in a report titled “The Uncertain Future of the Chip Shortage”.

“它们几乎为所有电子设备提供动力,包括汽车、计算机、传感器、游戏机、烤箱等,”他在题为“芯片短缺的不确定未来”的报告中说。

For most of the past two years, the aggregate chip lead time has been increasing, Uy said.

Uy 说,在过去两年的大部分时间里,总芯片交货时间一直在增加。

Last month was the first time since the start of the pandemic that this key metric fell, though ever so slightly, from 27.1 weeks to 27 weeks.

上个月是自大流行开始以来,这一关键指标首次从 27.1 周下降到 27 周,尽管下降幅度很小。

“While the decline is notable given the upward trend in lead times in the past couple of years, 27 weeks is still far from the norm, and we expect lead times to remain elevated going into 2023.

“虽然考虑到过去几年交货时间的上升趋势,下降是显着的,但 27 周仍远未达到标准,我们预计到 2023 年交货时间将保持较高水平。

“At the core of the chip shortage is the fact that most of the world’s advanced chips are manufactured in Taiwan and South Korea, and there are significant entry costs to penetrate this market,” he said.

“芯片短缺的核心是世界上大多数先进芯片都是在台湾和韩国制造的,要打入这个市场需要高昂的进入成本,”他说。

He also said that the pandemic has accelerated the pace of digitisation worldwide, and with this, the demand for consumer electronics.

他还表示,大流行加速了全球数字化的步伐,随之而来的是对消费电子产品的需求。

“Chips are the foundation of modern electronic devices, and as technology advances, so does the demand for chips,” he said, adding that electric cars can use 10 times the number of chips required for older cars and also require more advanced microchips.

“芯片是现代电子设备的基础,随着技术的进步,对芯片的需求也在增加,”他说,并补充说电动汽车可以使用旧车所需芯片数量的 10 倍,并且还需要更先进的微芯片。

In addition to cars, gaming consoles, electronic appliances and existing applications, the increasing use of artificial intelligence and big data in all facets of life will drive demand for advanced chips.

除了汽车、游戏机、电子电器和现有应用程序之外,人工智能和大数据在生活各个方面的使用越来越多,将推动对先进芯片的需求。

Uy also said that the chip shortage is indicative of larger supply-chain disruptions that have roiled the global economy, and caused inflation in many countries to spike to levels not seen in decades.

Uy 还表示,芯片短缺表明更大的供应链中断已经扰乱了全球经济,并导致许多国家的通胀飙升至数十年来未见的水平。

The chip sector is not immune to these price pressures.

芯片行业也不能幸免于这些价格压力。

“Both Intel and TSMC have indicated that they are raising prices later in the year and in 2023 because of rising raw material and production costs.

“英特尔和台积电都表示,由于原材料和生产成本上涨,他们将在今年晚些时候和 2023 年提高价格。

“This comes at a time when demand for consumer electronics is softening, though demand for automotive and data centre clients remains strong,” he said.

“这是在消费电子产品需求疲软之际,尽管对汽车和数据中心客户的需求仍然强劲,”他说。

Besides rising production costs, Uy said chipmakers are dealing with elevated lead times for lithographic machines and other production equipment.

Uy 表示,除了生产成本上升之外,芯片制造商还面临着光刻机和其他生产设备的交货时间延长的问题。

“As the situation normalises, we will see some divergence in the demand and supply balance for various chip applications.”

“随着情况正常化,我们将看到各种芯片应用的供需平衡出现一些分歧。”